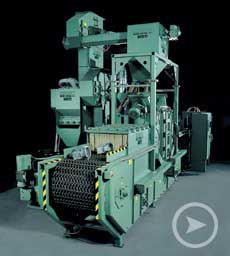

GOFF's Wire Mesh shot blasting machine models for continuous production feature a wire-mesh conveyor belt and are designed to offer high-production cleaning of various parts and castings. The Wire Mesh Design is simple and requires less material handling for faster and more productive throughput.

Parts placed on the wire mesh belt conveyor continuously pass through abrasive, tight-entry vestibule into the blast chamber. The quantity and placement of the blast wheels coupled with the blast wheel horsepower determine the cleaning capacity and production capabilities of each wire mesh shot blasting machine. The parts are blast cleaned - passing through the blast chamber and then exiting through the series of seals in the egress vestibule.

GOFF offers a complete line of stationary, airless centrifugal-blast cleaning machinery that clean items at a fraction of the cost of conventional air-blast cleaning methods. GOFF's direct-drive blast wheels offer consistent production and superior performance. The abrasive media is cleaned and recycled, reducing disposal and minimizing abrasive costs. Several machine groups are available, as well as specially engineered machines to meet individual requirements. Whichever wire mesh shot blasting machine model you select, GOFF's stationary, abrasive, continuous shot blasting machine models provide the performance you can count on for continuous production needs.